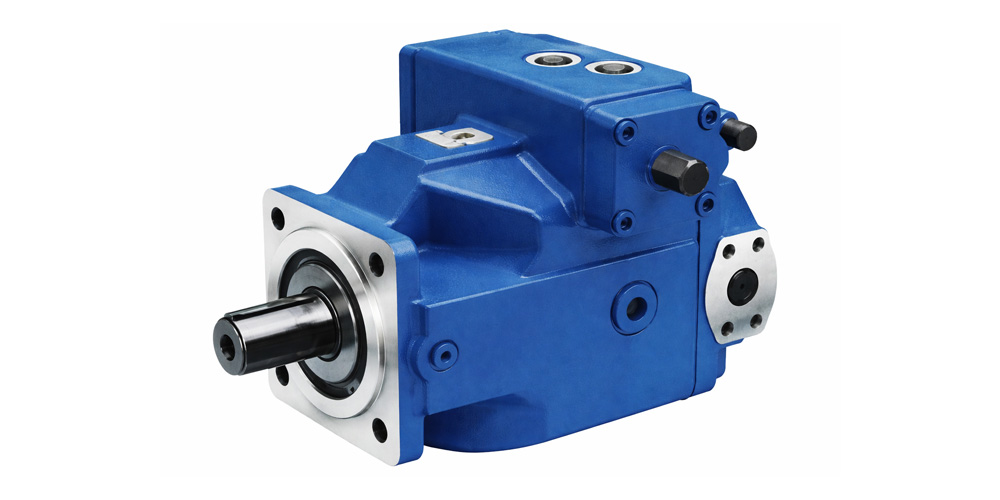

We provide precision repairing, overhauling, and performance restoration of axial and radial piston pumps used in CNC machines, injection molding, die-casting, power packs, and heavy industrial applications. Our repair process is engineered to restore original flow, pressure stability, and volumetric efficiency.

From internal leakage correction and swash plate reconditioning to piston–barrel matching, seal replacement, and servo control tuning, we deliver OEM-standard repairs that extend pump life, reduce downtime, and improve system reliability.

Comprehensive testing under actual working pressures to verify flow rate, pressure holding, leakage control, and operational stability before dispatch.

Our expert technicians are trained in repairing axial and radial piston pumps from leading OEMs, ensuring accurate tolerances, correct clearances, and long service life.

We eliminate pressure loss, noise, vibration, and overheating by correcting wear patterns, upgrading seals, and optimizing internal hydraulic paths.

End-to-end dismantling, inspection, lapping, component replacement, precision reassembly, and final testing as per OEM benchmarks and industry standards.